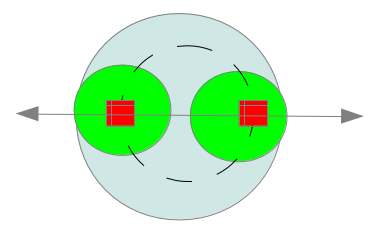

REBL has undergone big changes since the last report. The rotary stage is now gone. We recall that an early KLA-Tencor proposal was to have multi-column clusters arrayed on opposing sides of a circle as in Figure 1.

Entire wafer areas can be covered by moving the stage along one axis in addition to rotating. However, throughput was found to be inadequate, necessitating the addition of more column clusters. Unfortunately, with more clusters arrayed around the circle, one cannot cover the wafer areas by a simple one-dimensional stage motion. Instead, one must move each column cluster in and out radially. This is clearly not possible mechanically.

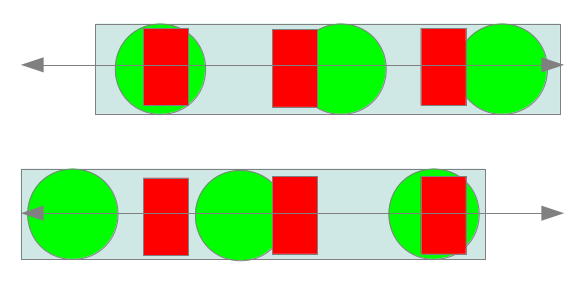

K-T’s latest proposal shows two X/Y maglev stages moving side by side in opposing directions. Each stage carries multiple wafers. (See Figure 2.) Obviously, this configuration suffers stage turn-around overhead. Because K-T targets the 16 nm node, and expects a higher dose requirement, they claim that the overhead is negligible.

K-T claims to have “some” functional modulator chips, but clearly continues to have difficulties here. The next column design (Column 4) due this year will operate at 100 kV and will have 100X demagnification. K-T expects 5 nm to 12 nm beam blur. Throughput will be limited to a few wafers per hour. Importantly, K-T may be targeting the cut pattern market rather than fully general patterning.